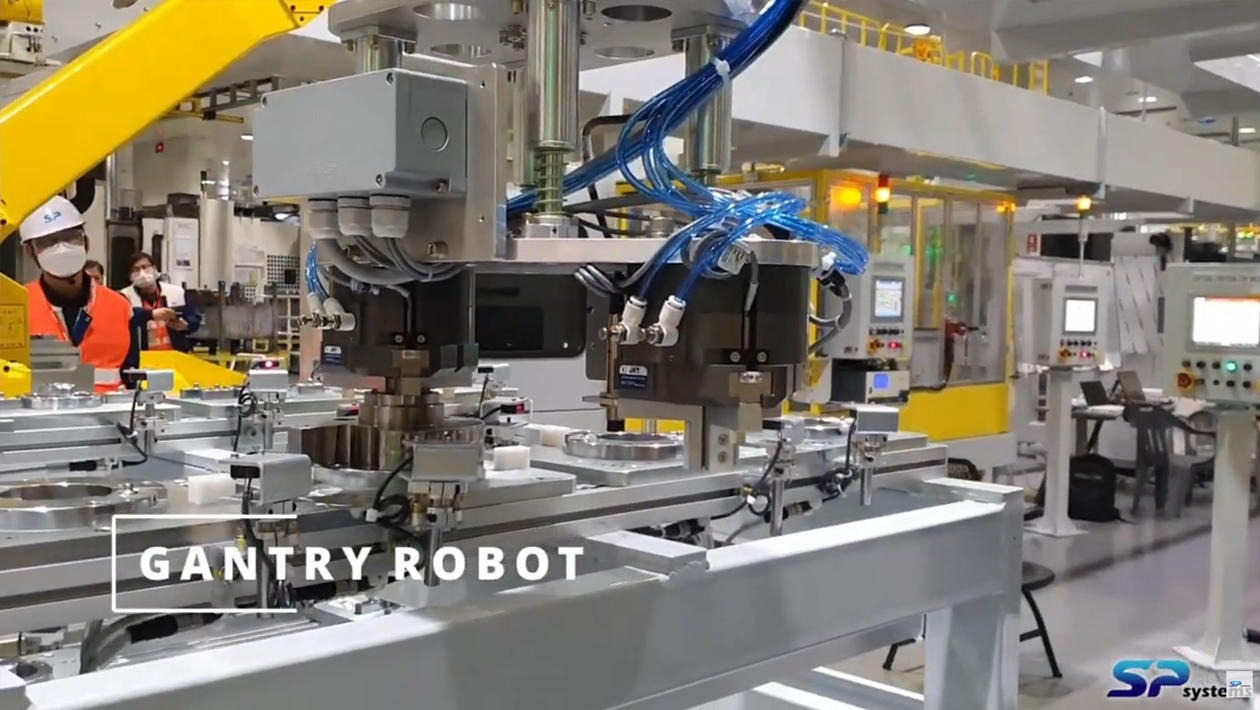

Gantry Robot Automation

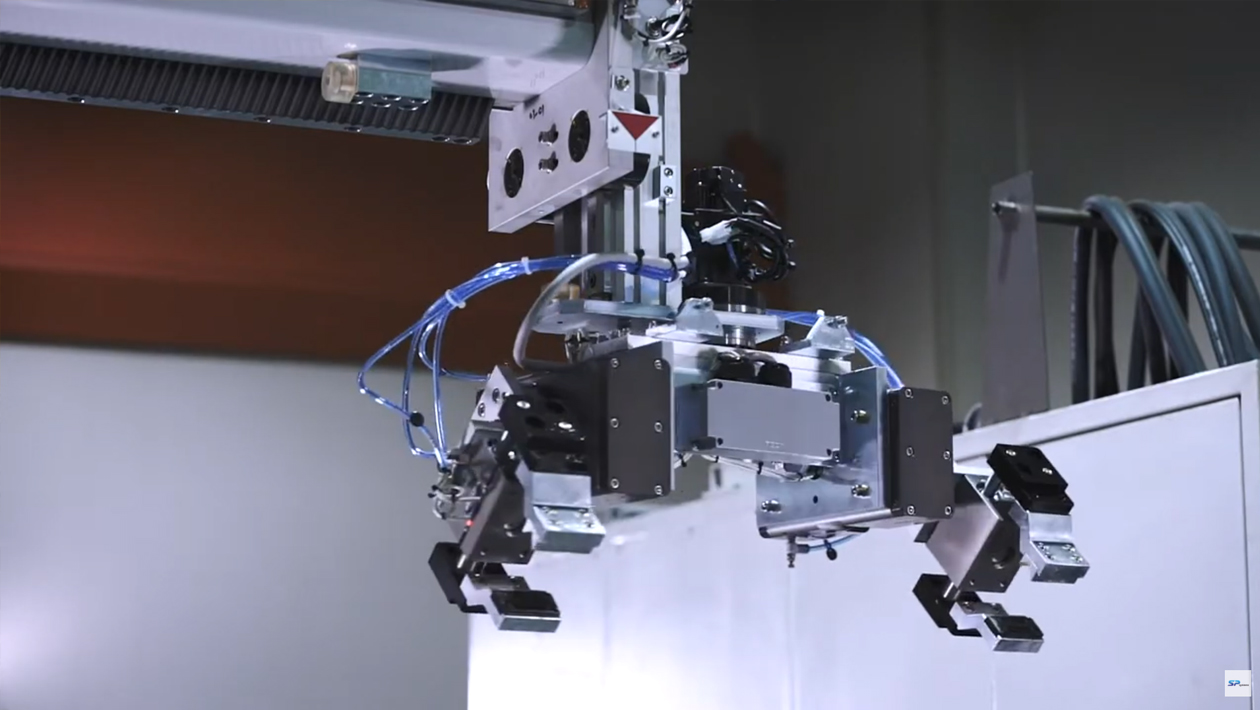

As a solution that allows the establishment of an unmanned automation system

for machine tool loading/unloading and all manufacturing processes using multi-axial gantry robots,

it is a solution optimized for heavy lifts and parts processing lines that are mass-produced.

Especially, it has the strengths of high-speed, high-precision transport, high space efficiency, unmanned automated operation,

reduced defect rate, enhanced productivity, etc. to become an essential automation solution for optimizing mass production,

expanding to various industries such as secondary batteries and aviation, etc.

Strengths & Effects

-

recenterIncreased Productivity

As it carries out working material import/export and movement of parts between processes to machine tools (machining center, CNC shelf, etc.), it maximizes productivity by minimizing the idle time of machine tools. Eases labor dependency and maximizes productivity as 24-hour unmanned automatic operation is possible

-

elevationReduced Defect Rate and Quality Enhancement

Reduces the defect rate as it allows quick and precise position decision by applying the servo control system Prevents defects due to scratches and shock, etc. that can occur during manual labor. Enhances product quality

-

paymentsCost Reduction

One gantry robot system can manage multiple machine tools, greatly reducing space and cost. Although it has a high introductory cost, it is highly effective in reducing labor and maintenance costs.

-

engineeringFlexible Line Composition

Allows relatively easy line adjustment and expansion even when changing product items and increasing facilities Can establish a smart factory by connecting with logistics robots (AMR, unmanned forklifts, cooperative robots, etc.) and automation facilities (conveyors, etc.)

-

expand_contentImprovement of Safety and Work Environment

Ensures the safety and health of workers by replacing repetitive heavy lifting tasks with robots Floor space can be used as it is installed at the ceiling of the factory, securing safety during worker or equipment movement.

Related Facilities

- Gantry robot

- Track motion

- Logistics automation equipment

- LMS

Completed tires undergo classification by model in the gantry warehouse, followed

by temporary storage. Subsequently, they are palletized and transferred to the Main logistics warehouse.

A solution where outbound tires from the main logistics warehouse are classified by model in

the gantry warehouse and palletized according to the requested shipment quantity before shipment.

Strengths & Effects

-

recenterMaximize Space Efficiency

Direct flat loading on the factory floor without a separate storage rack saves space and has high utility

-

elevationLogistics Management Optimiz

Connects with WMS (Warehouse Management System) to allow quick import/export of cargo and efficient stock management; the connection with logistics robots and automation facilities makes it advantageous in unmanned automation of the logistics system within the factory

-

autorenewOperation Flexibility

Allows loading and storage of various bulk material and heavy/large products,

The warehouse layout can be flexibly changed according to the form of the cargo, which can be applied to various industries -

paymentsCost Reduction

Saves on initial investment and maintenance cost as it does not need separate storage rack, stacker crane, shuttle, etc.

Saves on labor costs and optimizes operation efficiency as 24-hour unmanned operation is possible through connection with WMS

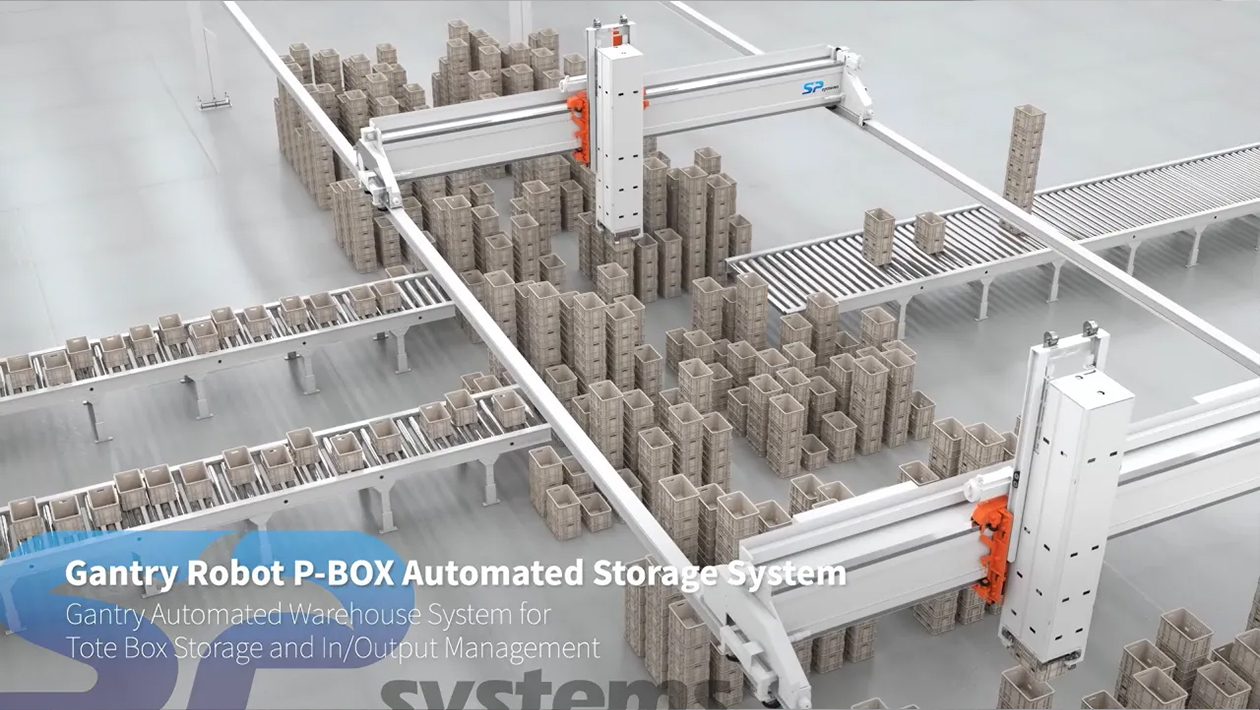

A solution that utilizes floor space to pick, store, and sort products in P-BOX units,

and is applicable to all types of cargo that allow multi-level stacking.

Strengths & Effects

-

recenterMaximize Space Efficiency

Direct flat loading on the factory floor without a separate storage rack saves space and has high utility

-

elevationLogistics Management Optimiz

Connects with WMS (Warehouse Management System) to allow quick import/export of cargo and efficient stock management; the connection with logistics robots and automation facilities makes it advantageous in unmanned automation of the logistics system within the factory

-

autorenewOperation Flexibility

Allows loading and storage of various bulk material and heavy/large products,

The warehouse layout can be flexibly changed according to the form of the cargo, which can be applied to various industries -

paymentsCost Reduction

Saves on initial investment and maintenance cost as it does not need separate storage rack, stacker crane, shuttle, etc.

Saves on labor costs and optimizes operation efficiency as 24-hour unmanned operation is possible through connection with WMS

A solution that enables the transfer and palletizing of heavy-duty steel boxes using a gantry robot,

and is capable of operating reliably in high-temperature environments.

Strengths & Effects

-

recenterMaximize Space Efficiency

Direct flat loading on the factory floor without a separate storage rack saves space and has high utility

-

elevationLogistics Management Optimiz

Connects with WMS (Warehouse Management System) to allow quick import/export of cargo and efficient stock management; the connection with logistics robots and automation facilities makes it advantageous in unmanned automation of the logistics system within the factory

-

autorenewOperation Flexibility

Allows loading and storage of various bulk material and heavy/large products,

The warehouse layout can be flexibly changed according to the form of the cargo, which can be applied to various industries -

paymentsCost Reduction

Saves on initial investment and maintenance cost as it does not need separate storage rack, stacker crane, shuttle, etc.

Saves on labor costs and optimizes operation efficiency as 24-hour unmanned operation is possible through connection with WMS

It is a solution optimized for transporting heavy objects

over 1 t and large products using high-payload gantry robots.

Gantry robots that allow transportation from 1 t to 5 t according to customer demands are standardized,

where ultra high-payload gantry robots over 5 t can be provided through special order. It is widely used in the automobile,

shipbuilding, steel, aerospace, construction materials, and logistics industries, with its scope of application continuously expanding.

Strengths & Effects

-

recenterMaximize Space Efficiency

Direct flat loading on the factory floor without a separate storage rack saves space and has high utility

-

elevationLogistics Management Optimiz

Connects with WMS (Warehouse Management System) to allow quick import/export of cargo and efficient stock management; the connection with logistics robots and automation facilities makes it advantageous in unmanned automation of the logistics system within the factory

-

autorenewOperation Flexibility

Allows loading and storage of various bulk material and heavy/large products,

The warehouse layout can be flexibly changed according to the form of the cargo, which can be applied to various industries -

paymentsCost Reduction

Saves on initial investment and maintenance cost as it does not need separate storage rack, stacker crane, shuttle, etc.

Saves on labor costs and optimizes operation efficiency as 24-hour unmanned operation is possible through connection with WMS

Applied Products

- Gantry robot

- Track motion

It is a customized solution created using an automated system that utilizes gantry robots

in the shuttering and de-shuttering process, which is key to the Pre-cast concrete double-wall

manufacturing method for construction.

If concrete deposition and curing are completed after the gantry robot automatically places the shutter at the precise location

in connection with the CAD/CAM data management system, the scattered shutters perceive the location through laser scans

for the gantry robot to remove and collect automatically. Likewise, core processes that depended on manual labor were automated

to enhance productivity greatly, serving as an essential solution for establishing smart factories in the field of construction.

Strengths & Effects

-

elevationEnhanced Productivity and Reduced Defect Rate

The blueprint information is reflected in real time to allow fast and accurate repetition of shuttering/de-shuttering tasks to enhance production speed and uniformize product quality By gently handling ferromagnetic shutters through precise control, product damage is prevented and defect rate is minimized Work speed greatly increases compared to manual labor by efficiently placing various types of shutters by length according to the size of the concrete panel in a short amount of time

-

paymentsCost Reduction

Reduced labor burden and cost by easing the dependency on experienced workers

-

engineeringEnhanced Safety

Reduced worker risk by replacing heavy payload handling tasks with robots. Improved work environment

Applied Products

- Gantry robot

- Blueprint information conversion system

The gantry robot-based welding automation system is an optimal solution

that automates the precise welding of large structures and heavy products that can maximize effects

such as enhancing productivity, stabilizing quality, securing safety, reducing cost, etc.

Multi-joint-type welding robots can be combined with multi-axial gantry robots for movement in all desired X, Y, and Z directions,

allowing high-speed, high-precision welding. Especially, it is establishing itself as an essential automation solution in the shipbuilding, steel,

construction, and aviation industries, and it is expected to develop further through connection with AI-based welding optimization technology.

Strengths & Effects

-

hideAllows Welding of Large Structures

and Various ShapesIt makes welding tasks for large structures and complex shapes efficient by combining multi-joint ARM and multi-axial gantry robots that can move in the X, Y, and Z directions. Automatic recognition of the welding part by applying laser scanner and vision system. Provides customized welding solutions for various shapes

-

elevationEnhanced Productivity

and Reduced Defect RateMaintains consistent quality and increases the welding speed by about 30–50% compared to manual labor through servo motor-based precise control Removes defects and minimizes reworking through AI and sensor-based welding pattern optimization Maintains constant quality through welding bead automatic tracking and inspection system. Reduced defect rate

-

paymentsCost Reduction

Reduces labor costs by easing the dependency on experienced welders as unmanned 24-hour operation is possible Reduced maintenance and quality management costs due to reduced defect rate following the stabilization of welding quality

-

engineeringEnhanced safety

Enhances worker safety as unmanned automated tasks are possible in the hazardous welding environment due to heat, gas, light, etc. Prevention of industrial disasters and creation of a safe work environment