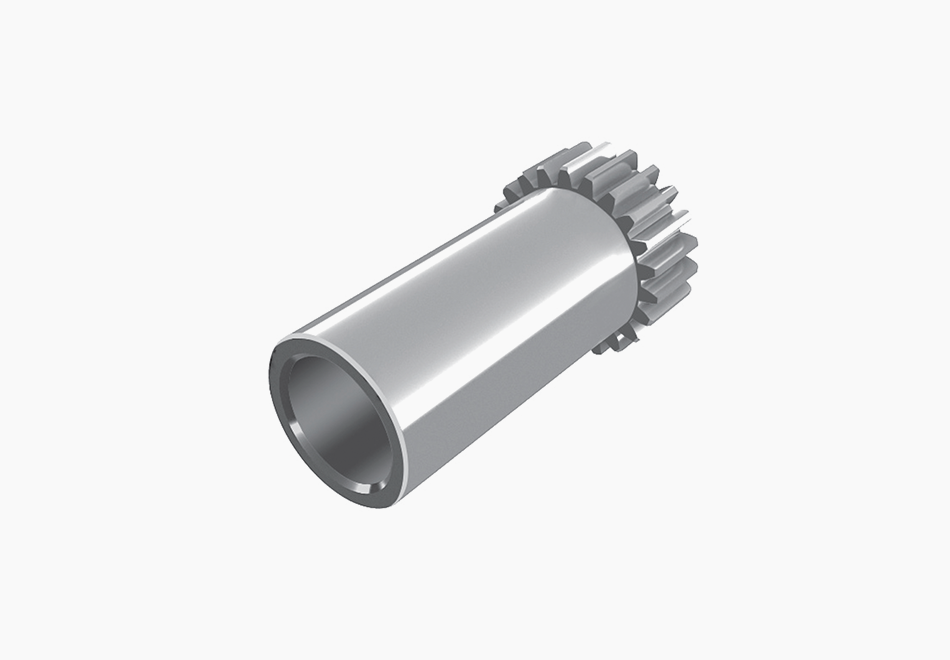

The servo gear box was designed as a serial equipment to various servo motors.

It is a traditional power transfer device that rotates the output shaft as the servo motor transfers power to the sun gear. It rotates from gear to planet carrier, and from planet gear to ring gear.

The epicyclic gear method that is more efficient and which produces more torque compared to any other form of power transfer method is the most universal and ideal power transfer device.

Characteristics 01

-

stat_3

Output torque of more than 30% compared to normal bevel gear due to the application of spiral bevel gears

-

speed

Allows up to 8x higher input speed compared to normal bevel gear

-

screenshot_region

Increased weight dispersion ability through precise gear design, along with extending its lifespan

Characteristics 02

-

precision_manufacturing

The gear is designed and processed through precise gear design programs, operating naturally and quietly even with low backlash (≤ 2 arcmin)

-

build_circle

Maintains high strength by applying light but high-tension aluminum housing

-

oil_barrel

Does not require maintenance as high-performance lubricant is applied

Characteristics 03

-

autorenew

Applied sealing design specialized for high speeds and repeated operation

-

volume_down

High efficiency of 95% and low noise of 61B

-

tune

Retains various moderation ratios from 3 to 20