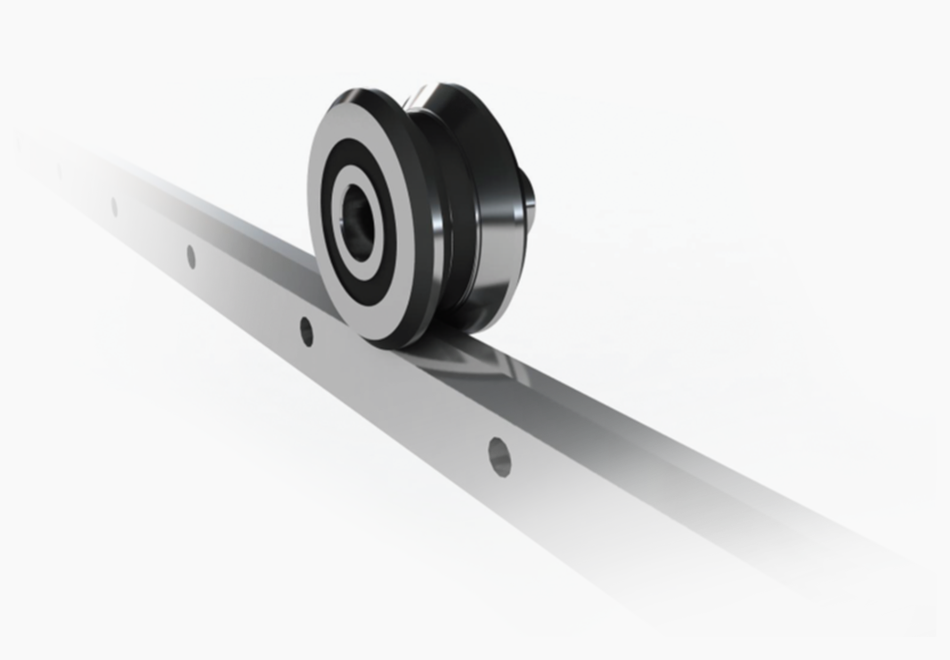

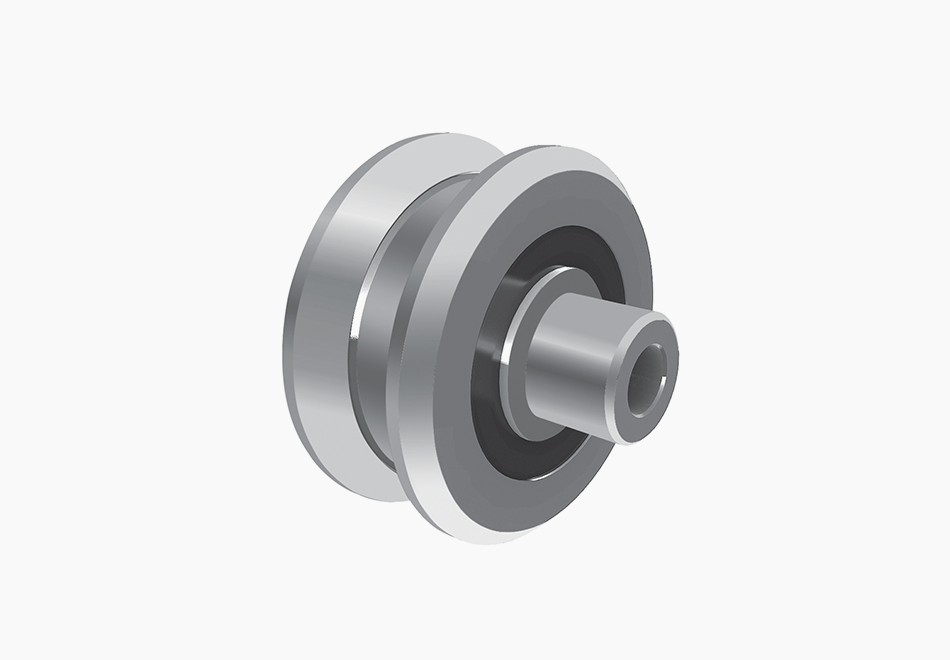

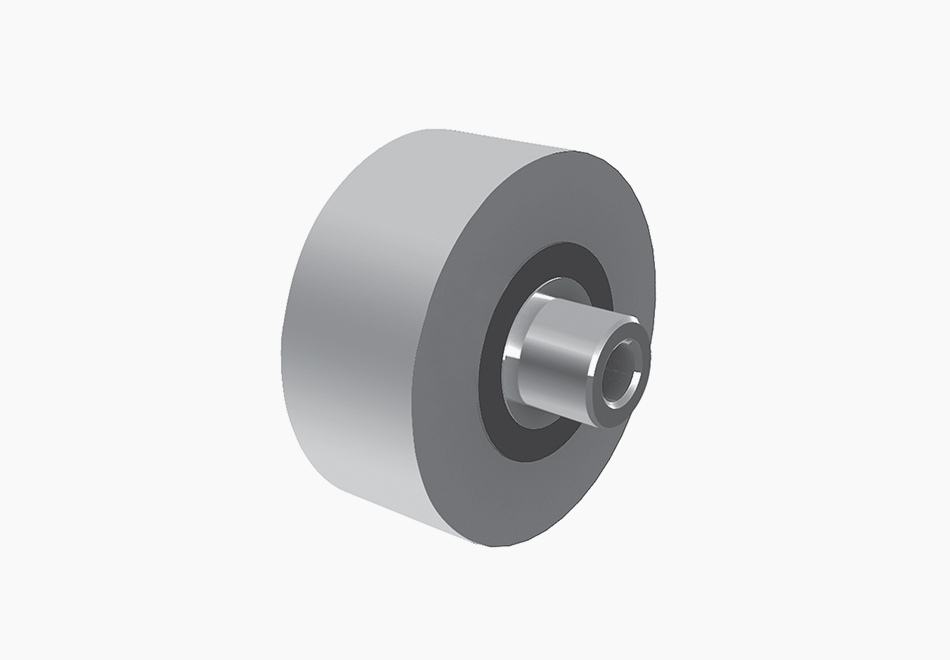

The guide roller is manufactured using precise tolerance-level recuperative angular contact ball bearings with a strong structure for heavy-weight tasks, increasing it towards the axis and radial directions.

The roller is sealed to preserve the lubrication of the bearing with the roller surface finely rounded to reduce friction during rotation, allowing error correction for assembly or slight bending of the guide.

Standard Measurements and Specifications

| Product Size | Bearing Distance(μm) | Bearing Tolerance Rating | Friction Coefficient |

|---|---|---|---|

| 20 | min,6/ max,23 | PN | 0,01~0,03 |

| 25 | min,8/ max,27 | ||

| 35 | min,11/ max,33 |

Preload

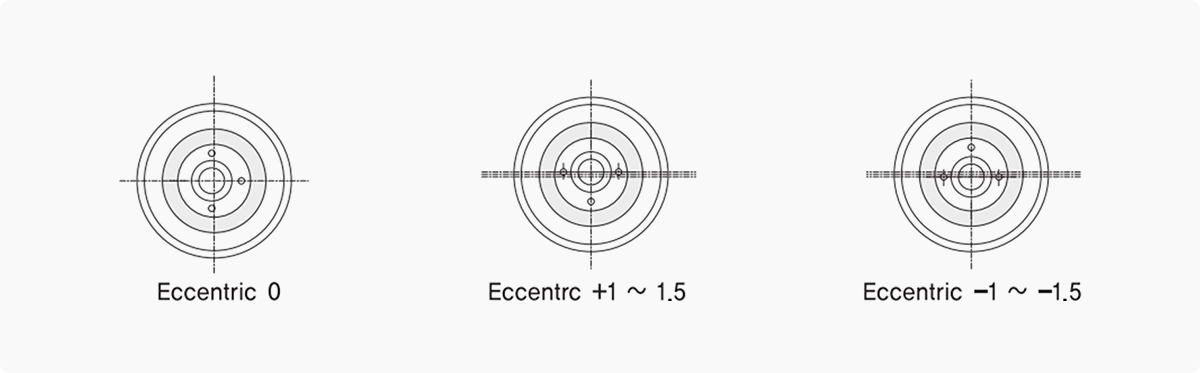

All guides are produced as a fixed, eccentric version to adjust the backlash during final equipment assembly, where E is additionally marked on each eccentric roller model name.

The inner axis of the eccentric guide roller is provided with 3 holes. Precompression is adjusted through these holes.